This year, we bought a half a pig as an alternate food sourcing and storage exercise. These would be raised and butchered by ourselves. DIY meat. Here’s the story, from piglet to pork chop.

Promoting The Idea

Our pastor had been talking about maybe raising pigs off and on for a couple years. I suggesting that he let others in the church ‘buy in’ — CSA style — to offset some of his costs. Whenever he pipe dreamed about it, I was very encouraging. Perhaps it was my nag-encouragement, but this spring, he finally acted on the idea.

We bought in for half a pig. $75. Another church member was raising lambs for meat, he offered a lamb in exchange for half a pig. Yet another church member bought in too. We had investors. The deal was on.

Getting The Piglets

Acquiring piglets wasn’t quite as easy as going down to Tractor Supply during “Chick Days” and coming home with a box of chicks. No, breeders “sell” piglets before they’re even born. They calculate when their sows will give birth, then a six-week weening period, before piglets are ready to sell. They line up buyers accordingly. And, there are a lot of buyers. It took a few weeks for the pastor to get on a breeder’s Wait List. Finally, he was in the queue. Part of a litter born in early May would be his. He could take delivery in mid June. $150 per piglet. He opted for three. One for his own family, the other two being divvied up among the other “investors.”

Getting the “House” in Order

Pigs need someplace secure to stay as they grow large. Catching runaway pigs is very difficult. The church property still had garage-like shed out back that had, a few years earlier, housed a couple of horses. The pastor was horse-sitting for a member’s daughter who was in “housing transition.” Fencing for pigs needed to be much more robust than for horses.

As an example of “the Lord provides,” the pastor’s son, who works construction, salvaged 100 feet of 6’-tall chainlink fence that was being thrown away. Fence poles too. Free fence! With some heavy logs around the perimeter to prevent rooting-lifting, the stye was ready. The three little pigs arrived to a spacious (as long as they were small) home.

Feeding For Cheap

Those pigs were going to eat a lot. The Lord provides, again. Earlier in the year, one of the church’s regular attendees — a night manager at a grocery store — began bringing “expired” goods to the church for members to take home. The store was happy to have her take some of it. They were going to throw it away anyhow. At first, It was just bakery goods, but expanded to include produce, dietary supplements, coffee, and occasionally frozen chicken or fish. This has been a boon for church members. I had brought home many quarts of strawberries that had one or two moldy ones. Chuck the moldy ones. Clean, slice and dehydrate the rest. The same for mushrooms. This added many pints of dried fruit to our home food supplies.

When the pigs arrived, they had more free food than they could eat. Anything too far gone for the church folks was perfect for pigs. They ate very well. It was a win-win for the grocery store, the pastor, and the pigs. And, indirectly, me!

Such free pig food isn’t that unique. The neighbor of another church member gets free castoff produce from a different grocery store for her pigs. All she has to do is ask.

Harvest Time

NOTE: I won’t go into the graphic details. But, if the sight of raw meat upsets you, you might want to stop reading. There are butchering photos below.

Come November, the three (now giant) pigs were at full market weights of 250 to 300 lbs. They were ‘retired’ one at a time, as the processing was not going to go fast enough to do all three in a day. The pastor processes his own deer each year, so he had an idea of how long it might take.

After each pig had been hung for a few days in the 30-degree weather to chill, it was time to begin cutting. The pastor bought a battery-powered reciprocating saw to do the big (bone) cuts. The carcass was transferred from the tree it hung on to hanging from the bucket of a tractor. The first cut was to split the carcass in two.

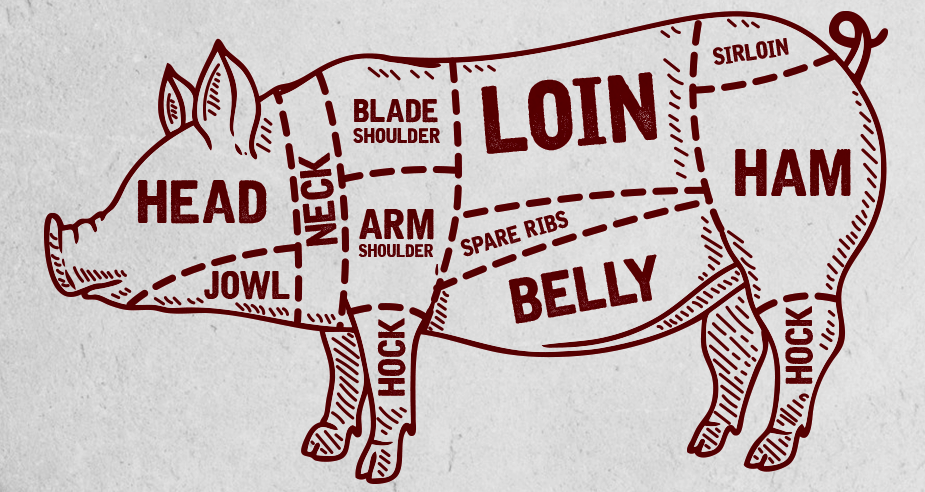

An old friend of the church’s head deacon is a butcher at a local grocery store. He volunteered to show the pastor a few tips on dividing up a whole pig. He was telling us that his skills were becoming less common in grocery store butchers. The stores doesn’t get whole pigs to cut up anymore. Typically, the store get quarters or large cuts to trim down to retail portions. He was old school so knew his way around a whole pig.

Of course, it’s not nearly as simple as the classic “Cuts of a Pig” diagrams suggest.

I brought home the bigger pieces in two big coolers that I could keep out on the deck, on account of the 15-degree nights and 30-degree days. It was a refrigerator outside. Making ice was as simple as leaving trays of water outside overnight.

I cut the tender and boneless pieces into chops, steaks and the smaller bits into stew chunks. Odd trimmings went into the “grind” bowl.

The larger pieces were divided into several “roasts” — at least, that’s what I’m calling them. A section of shoulder I set aside for salting into a dry-cured country ham. Two of the rear leg hams would get wet-brined as ‘city hams.’ The belly cut and sides were trimmed to become bacon — one wet-brined, the other two as dry cured.

The dry cured pieces won’t be ready until February or March. Dry curing is the old traditional method for preserving pork over the winter (before refrigeration). I tried that last year and want to do it again.

All those roasts and sections of ribs filled up the rest of what freezer space I had left.

Soup Stock

Nothing goes to waste. The boney parts with too little meat on them to bother cutting away, got boiled in a big stock pot — actually, our hot-water-bath canner. With a quart of canned tomatoes from the garden harvest and some spices, the bones yielded about three quart jars of soup stock. These, we pressure canned and added to the shelf.

Chicken Treats

Also in the spirit of ‘nothing goes to waste’… There was about a cereal bowl’s worth of meat that could be picked off the boiled bones, which made two nice BBQ pork sandwiches for lunch. The stripped bones still had meat bits on them. They got tossed to the chickens who went into a feeding frenzy. They love picking slivers of meat off bones. Turn those bone scraps into eggs!

Fatty. Lardo.

Meat is only part of the story. Domesticated pigs are also famous for their fat. I was a little surprised how much fat there was on them. Along the back, there was a good two-inch layer of pure fat. The sides and belly were largely fat too. The harder fat around the liver, etc. makes a harder lard with a higher melting point, prized for making flaky pie crusts.

In the olden of days, all that fat was gold. People cooked with lard, baked with lard, even ate lard sandwiches. (I’m not quite up to that) Lard was THE cooking fat until Proctor & Gamble convinced cooks that Crisco (originally cottonseed oil, hydrogenated to be solid at room temperature), was somehow healthier. I wanted to render down my own lard and cook like the pre-Crisco days.

To start, I cut up the fat into sugar-cube sized pieces. The smaller the better, for extracting the oil. I placed the bits in an old crockpot we seldom used. I let it run on Low for six or eight hours. This slowly cooked out the oil. Hotter is faster, of course, but it starts to ‘brown’ the oil, giving it more of a pork flavor. Slowly extracted oil imparts very little flavor.

The hot oil was then filtered through a paper towel into pint jars and lids screwed on tight. Overnight, the oil cooled and solidified into a semi-solid white lard. From the trimmings off my half-a-pig, I got seven pints of lard. We should be good for cooking grease for the winter.

The squishy fat chunks did not melt completely. About half the mass remained. You can fry them up into ‘Cracklins,’ they say, but I didn’t want to. Instead, I spooned the smaller chunks and residual oil into aluminum pans to cool and solidify. These became chicken treats too. They love fat — especially in the winter when they need the extra calories to generate body heat. They loved my homemade “suet.” Some of the suet has been hung out for the little birds. The titmice and woodpeckers are loving that suet. Nothing goes to waste.

Sausage Debut

Trimmings off of the various cuts yielded about two pounds of strips, bits, and chunks. These got saved in a bowl for sausage making. I’d never made sausage before, so I was looking forward to the experience.

My son-in-law’s family never made sausage out of their deer trimmings. They always made Scrapple — as sort of (raw) ground meat and corn meal meatloaf used rather like Spam. (Slice and fry) I wanted to try classic sausage, though after doing so, I can see the appeal to Scrapple. Lots easier to make.

A good sausage needs to be around 20% fat, they say, otherwise it comes out too dry. So, I saved a section of back fat to chunk up for sausage. When all the other cuts were salted, brined, or frozen, it was time to get out the grinder for the scraps.

I looked at many recipes but each one had something I didn’t have or didn’t want to do. A common sausage spice is fennel, but my wife really dislikes the taste of fennel seed, so all those recipes were out. I found a few garlic sausage recipes that I could adapt.

My First Sausage Recipe

What I used:

- 1000 grams of trimmed pork chunks (not super lean) (about 2.2 lbs.)

- 190 g of cubed back fat.

- 30 g canning salt

- 5 g Cure #1 (or Prague Powder #1)

- 10 g pressed garlic cloves

- 5 g coarse-ground black pepper

- 5 g coarse-ground coriander

The meat and fat went through the grinder once with the coarse disk, then back in the freezer to keep it cold. All the articles I read advised you to keep everything as cold as possible as the fat in the mix will liquify at warmer (room) temperatures and prevent the mix from sticking together. When that happens, you get loose, crumbly sausage, they say.

After some chill time, the spices were tossed amid the coarse grind, using a wooden spoon, not hands, lest the hands warm up the mix. This spiced mix was then run through the grinder again (kept outside between uses to keep it cold too) using the fine disk.

A test patty of this fine grind was cooked and actually tasted quite good: a pleasant surprise for my first ever batch. The coriander has a mild, woody-peppery taste that seemed perfect for sausage. My mix turned out a little saltier than it should have because I didn’t think 30g of salt looked like enough for the 2.5 lbs. of mix to brine properly. I did another 10g. I shouldn’t have added more. 30g was enough. But, I didn’t mind the slightly saltier taste.

The fine grind was then packed into the sausage stuffer (also chilled outside). The natural sheep casings (clear) made for better looking sausages and probably better for eating, but the natural casings were quite difficult to make usable.

I also used some collagen casings (Red). These were much easier to use, but reviews suggest that they’re not as good for eating. Papery? I made some of each so I could compare. The finished links hung in my cold garage for several hours to dry and ‘set.’

Conclusion

Finishing the cutting of the half-a-pig was a fair amount of work, over several days to get all the big cuts trimmed into portions and processed (with other chores to tend between operations). But, that’s what people have had to do for thousands of years in order to have protein for the winter. Buying your pork chops or bacon already cut and packaged is certainly faster and easier. This experience, however, taught me a lot.

If the pastor is up for doing CSA pigs again next year, and it sounds like he is, I’ll do another half-pig. Next year, my sausage won’t be on the salty side. Of course, doing another half-a-pig means that before then, I need to eat the half pig that’s filled my freezer and hanging to cure if I’m to have room for another one. Oh dear. Forced to eat ham, bacon and pork roasts. Oh no! 🙂

—

Me thinks the lady protests too much LOL

FORCED to eat prime pork.

Excellent report. Will be very interested in your dry cured ham and bacon results.

Yeah. Such a problem, eh? Nice to have a little pork to go with the beans and rice.

I’ll be keen to see how the dry cures turn out too. Hoping it’s good, as it’s a nice non-grid storage option.

— Mic